Large number of launch failures

Quote from Brian C. on December 5, 2022, 9:48 amSo, I am noticing that we have a significant number of ignition failures at each club launch. This is happening to newbies and experienced rocketeers alike, so, it isn't just about "user error" of failing to install the ignitor correctly. I'd like to ask that whomever has the club system in their basement go through the system and clean the clips in preparation of our next launch.

The other thing is that I think our wires are heavy, and these are pulling the ignitors (and the little plastic plugs) out a little bit when we attach the leads/clips. Not sure yet what we can do about that, but it's something we should investigate. I am thinking about building a thin set of leads with micro-clips and then rigging that to the club's aligator clips for next month, so there's less weight pulling on the ignitor. I may then also buttress the plastic plug with a bit of masking tape. Hopefully, that will insure it won't take me 3 tries to get a bird in the air.

So, I am noticing that we have a significant number of ignition failures at each club launch. This is happening to newbies and experienced rocketeers alike, so, it isn't just about "user error" of failing to install the ignitor correctly. I'd like to ask that whomever has the club system in their basement go through the system and clean the clips in preparation of our next launch.

The other thing is that I think our wires are heavy, and these are pulling the ignitors (and the little plastic plugs) out a little bit when we attach the leads/clips. Not sure yet what we can do about that, but it's something we should investigate. I am thinking about building a thin set of leads with micro-clips and then rigging that to the club's aligator clips for next month, so there's less weight pulling on the ignitor. I may then also buttress the plastic plug with a bit of masking tape. Hopefully, that will insure it won't take me 3 tries to get a bird in the air.

Quote from Admin on December 5, 2022, 10:41 amCharlie has the club's equipment.

You're welcome to make some small pigtail leads and use them. Tag any wires and other personal launch kit with your name so that when teardown comes around, they don't get stashed away with the club's kit.

I have a cache of the small toothless alligator clips, akin to the type Estes supplies on its launch system, that I could employ to fashion a few such pigtails. The clips I have are better because they're formed with a reinforcement ridge in the flat portion of the jaw. I'll make a few up with lighter gauge wire and some gold plated quick disconnect tabs. I recently purchased a roll of 28 gauge red/black wire (for wiring my av-bay electronics) which is really light wire.

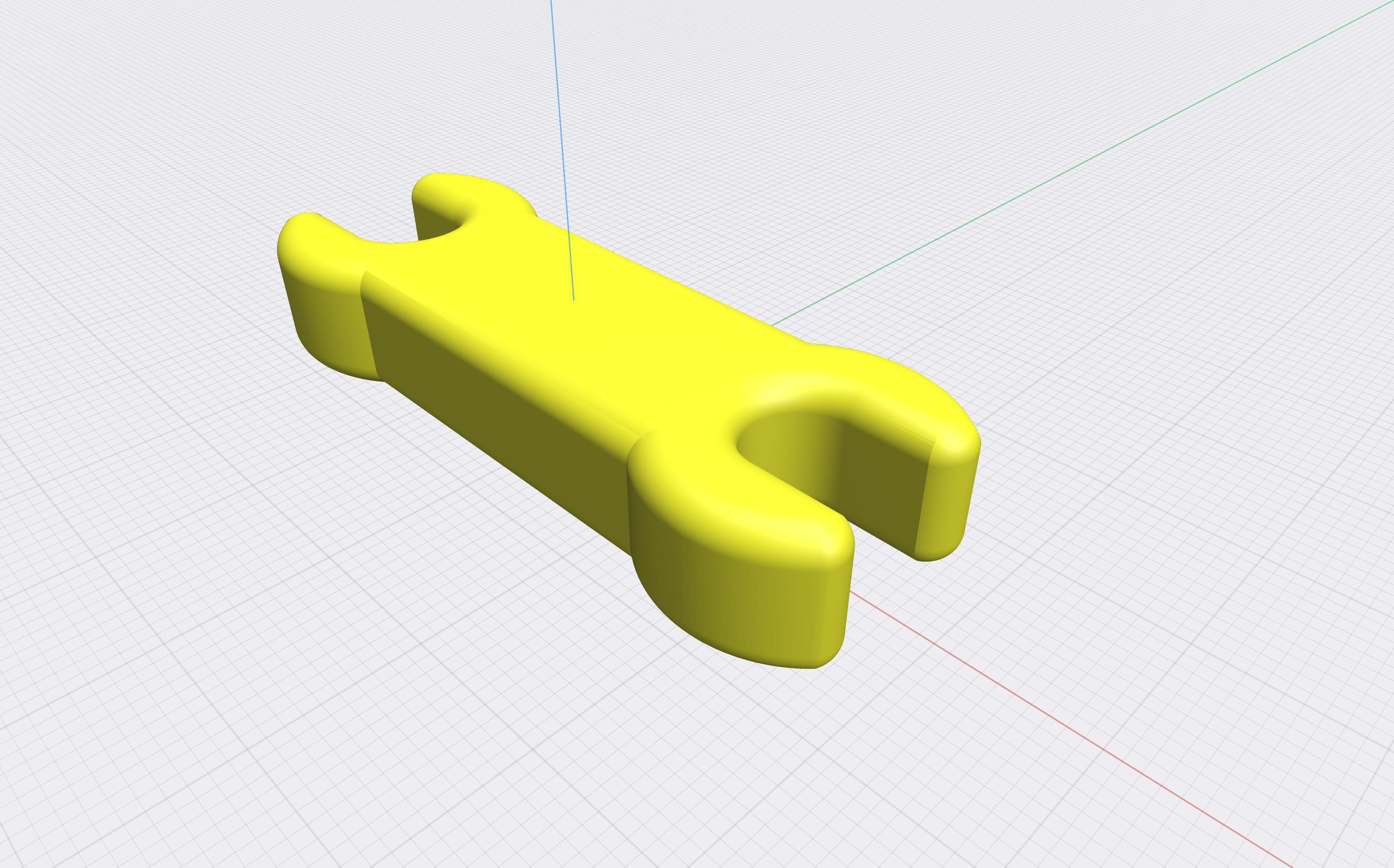

I have 3D printed some "spacers" for use with the club's wires. Helium-brained, I left the bag of the 30 spacers I had printed on the bench in the "rocket room". Next launch for sure! I designed these to keep the clips from shorting.

As for igniters, the Estes igniters NO LONGER have a pyrogen on them. That coating is merely a prophylactic to protect the nichrome bridge wire. That wire MUST contact the grain to ignite the motor. The wire only glows red-hot, nothing more. In one of the NAR "Sport Rocketry" magazines a year or so ago, there was an article on augmenting the Estes igniters with a fabric glue and some black powder. I have been using collodion and black powder to augment mine. I've given these to some club members in the past whenever they had an onerous issue with igniting their motors. They're pretty much guaranteed to ignite an Estes motor. For the LARGER of the Estes motors — D, E and F — their nozzle throats are large enough to cram an e-match into. Those never (99.99999% of the time) fail to spawn ignition.

Charlie has the club's equipment.

You're welcome to make some small pigtail leads and use them. Tag any wires and other personal launch kit with your name so that when teardown comes around, they don't get stashed away with the club's kit.

I have a cache of the small toothless alligator clips, akin to the type Estes supplies on its launch system, that I could employ to fashion a few such pigtails. The clips I have are better because they're formed with a reinforcement ridge in the flat portion of the jaw. I'll make a few up with lighter gauge wire and some gold plated quick disconnect tabs. I recently purchased a roll of 28 gauge red/black wire (for wiring my av-bay electronics) which is really light wire.

I have 3D printed some "spacers" for use with the club's wires. Helium-brained, I left the bag of the 30 spacers I had printed on the bench in the "rocket room". Next launch for sure! I designed these to keep the clips from shorting.

As for igniters, the Estes igniters NO LONGER have a pyrogen on them. That coating is merely a prophylactic to protect the nichrome bridge wire. That wire MUST contact the grain to ignite the motor. The wire only glows red-hot, nothing more. In one of the NAR "Sport Rocketry" magazines a year or so ago, there was an article on augmenting the Estes igniters with a fabric glue and some black powder. I have been using collodion and black powder to augment mine. I've given these to some club members in the past whenever they had an onerous issue with igniting their motors. They're pretty much guaranteed to ignite an Estes motor. For the LARGER of the Estes motors — D, E and F — their nozzle throats are large enough to cram an e-match into. Those never (99.99999% of the time) fail to spawn ignition.

Uploaded files:

Quote from Eric Becher on December 5, 2022, 11:39 amDirty clips can sometimes be an issue. If you see some that are fouled, we usually have some sand paper and can clean them up. Or you can volunteer to help Charlie clean up the rods and clips after each launch. 😁

I have the occasional failure to launch, but I don't think I have too many as long as I am paying careful attention to:

- Make sure the igniter/starter/initiator is touching the propellant, and also not shorting out itself (a common source of problems). I try to carefully pull the starter wires apart slightly before inserting them into the nozzle. I can show you at the next launch.

- Careful placement of the clips on "good wire" (not the paper) and squeezing them down so they are holding tight.

- Keep the clips apart by either putting the clothes pin between them, or running the wire leads around opposite sides of the launch rod so they naturally pull apart, not fall in together.

Hope that helps, but your and Brian's other suggestions sound like nice ideas too.

Dirty clips can sometimes be an issue. If you see some that are fouled, we usually have some sand paper and can clean them up. Or you can volunteer to help Charlie clean up the rods and clips after each launch. 😁

I have the occasional failure to launch, but I don't think I have too many as long as I am paying careful attention to:

- Make sure the igniter/starter/initiator is touching the propellant, and also not shorting out itself (a common source of problems). I try to carefully pull the starter wires apart slightly before inserting them into the nozzle. I can show you at the next launch.

- Careful placement of the clips on "good wire" (not the paper) and squeezing them down so they are holding tight.

- Keep the clips apart by either putting the clothes pin between them, or running the wire leads around opposite sides of the launch rod so they naturally pull apart, not fall in together.

Hope that helps, but your and Brian's other suggestions sound like nice ideas too.

Quote from Brian C. on December 5, 2022, 12:57 pmI'd be happy to give the rods and clips some sandpaper scrubbing as we are setting up next month (as long as it isn't bitterly cold), and see how that goes.

FYI: some internet wisdom is to dip the estes ignitors in testor's metallic silver paint (apparently flammable?) -- I'll have to check that out and perform a test at home. I also saw a video on youtube where the advice is to hold the head of the ignitor, pull the wires apart slightly so that inserting the plastic plug doesn't cause them to short.

All good advice. There's a lot of learn and a good number of steps to go through to insure a successful light.

I'd be happy to give the rods and clips some sandpaper scrubbing as we are setting up next month (as long as it isn't bitterly cold), and see how that goes.

FYI: some internet wisdom is to dip the estes ignitors in testor's metallic silver paint (apparently flammable?) -- I'll have to check that out and perform a test at home. I also saw a video on youtube where the advice is to hold the head of the ignitor, pull the wires apart slightly so that inserting the plastic plug doesn't cause them to short.

All good advice. There's a lot of learn and a good number of steps to go through to insure a successful light.

Quote from Admin on December 5, 2022, 1:56 pmActually, I've read that clear nail polish is mostly nitro-cellulose which is highly flammable. That nail polish and a little dip into black powder before the nail polish is set should suffice.

Actually, I've read that clear nail polish is mostly nitro-cellulose which is highly flammable. That nail polish and a little dip into black powder before the nail polish is set should suffice.

Quote from oliverhub on April 9, 2024, 11:11 amCan we talk about Shock Cords?

Abnormal number of separation events this week. Are there any autopsy reports from ARC teams? Curious & concerned. Material or construction failures? Knot my fault?

Chris Oliver

Can we talk about Shock Cords?

Abnormal number of separation events this week. Are there any autopsy reports from ARC teams? Curious & concerned. Material or construction failures? Knot my fault?

Chris Oliver

Quote from Admin on April 9, 2024, 12:35 pmQuote from oliverhub on April 9, 2024, 11:11 amCan we talk about Shock Cords?

Abnormal number of separation events this week. Are there any autopsy reports from ARC teams? Curious & concerned. Material or construction failures? Knot my fault?

Chris Oliver

PET PEEVE ALERT!!!

I've seen this problem even with college aeronautical engineering students attempting certification level flights. The A.E. students and these ARC students do not seem to have a respect for the forces of flight. I believe that some of it can be attributed to the age-old Estes shock cord mounting scheme; however, most of these ARC teams have never built nor flown even a small Estes rocket, so putting the oneness on Estes is probably less of a factor. Anything flying over a D, in my not so humble opinion, should not be using the anchor-to-the-airframe-wall method for the shock cord tethering. Attachment for such rockets should be made around the MMT or anchored through a centering ring such as is done for most high power rockets.

Should I be club president for another term, ANY ARC rockets will need to pass a safety inspection to fly. There was one team on Sunday that had cellophane taped their fins!!! These ARC teams have had months to put together their rockets, so there's no excuse for showing up this last launch presenting with rockets that look like they were assembled en route to the launch.

Another team — I observed this after moving the rails that the ARC teams were using farther east — used rail buttons that were pushed through the airframe (cardboard tube) via a hole that looked like it was punched with an awl. The screw really had NOTHING to bind to and, while threading the rocket on the rail, the rail-button easily pulled loose.

The NAR is also partly to blame for this. ARC students signing on for the America Rocketry Challenge should be required to fly from the signing on get-go as often as possible. This would give them more experience with rocketry which, it appears from what I've observed, they simply do not possess. It's not just the ARC teams either. I had one college engineering student who signed on to her college's rocketry team which is involved with the Spaceport America Cup. I believe that SAC or their school club require the team members to be High Power Rocketry certified. This student had NEVER flown a rocket of any type but was seeking L1 High Power certification.

This is a problem with the "participation trophy" generation. Their lack of experience puts them into the "safety risk" pool and it could jeopardize our club.

Quote from oliverhub on April 9, 2024, 11:11 amCan we talk about Shock Cords?

Abnormal number of separation events this week. Are there any autopsy reports from ARC teams? Curious & concerned. Material or construction failures? Knot my fault?

Chris Oliver

PET PEEVE ALERT!!!

I've seen this problem even with college aeronautical engineering students attempting certification level flights. The A.E. students and these ARC students do not seem to have a respect for the forces of flight. I believe that some of it can be attributed to the age-old Estes shock cord mounting scheme; however, most of these ARC teams have never built nor flown even a small Estes rocket, so putting the oneness on Estes is probably less of a factor. Anything flying over a D, in my not so humble opinion, should not be using the anchor-to-the-airframe-wall method for the shock cord tethering. Attachment for such rockets should be made around the MMT or anchored through a centering ring such as is done for most high power rockets.

Should I be club president for another term, ANY ARC rockets will need to pass a safety inspection to fly. There was one team on Sunday that had cellophane taped their fins!!! These ARC teams have had months to put together their rockets, so there's no excuse for showing up this last launch presenting with rockets that look like they were assembled en route to the launch.

Another team — I observed this after moving the rails that the ARC teams were using farther east — used rail buttons that were pushed through the airframe (cardboard tube) via a hole that looked like it was punched with an awl. The screw really had NOTHING to bind to and, while threading the rocket on the rail, the rail-button easily pulled loose.

The NAR is also partly to blame for this. ARC students signing on for the America Rocketry Challenge should be required to fly from the signing on get-go as often as possible. This would give them more experience with rocketry which, it appears from what I've observed, they simply do not possess. It's not just the ARC teams either. I had one college engineering student who signed on to her college's rocketry team which is involved with the Spaceport America Cup. I believe that SAC or their school club require the team members to be High Power Rocketry certified. This student had NEVER flown a rocket of any type but was seeking L1 High Power certification.

This is a problem with the "participation trophy" generation. Their lack of experience puts them into the "safety risk" pool and it could jeopardize our club.

Quote from Brian C. on April 9, 2024, 6:19 pmIt just astounds me that so-called "engineering students" know so little about actual engineering. And yes, they seem to go from zero to F-motor with nothing in-between, which seems like a recipie for not just failure, but potential injuries. There should be a REQUIREMENT to build an Estes kit that uses an 18mm motor before you are flying a 29mm bomb.

I've been flying rockets for 2 years now, and I'm still not L1, although that is in my plans for this year. But in that 2 years, I've built and flown close to 100 rockets, quite a few of my own design. And they range from 18mm to 29mm motors. Actually, I have a few that are 38mm -- but I haven't flown those yet. I may adapt down my LOC-IV down to 29mm to fly at CENJARS... but I digress.

The point is, things like how tight your nosecone needs to be you can only ascertain via experience, this isn't something you can google and get a good answer to. Tick-Tok doesn't help either. I think a lot of people think they can just waltz into this and get their "A" grade without doing actual work. Rocket Science isn't easy, just ask any rocket scientist!

It just astounds me that so-called "engineering students" know so little about actual engineering. And yes, they seem to go from zero to F-motor with nothing in-between, which seems like a recipie for not just failure, but potential injuries. There should be a REQUIREMENT to build an Estes kit that uses an 18mm motor before you are flying a 29mm bomb.

I've been flying rockets for 2 years now, and I'm still not L1, although that is in my plans for this year. But in that 2 years, I've built and flown close to 100 rockets, quite a few of my own design. And they range from 18mm to 29mm motors. Actually, I have a few that are 38mm -- but I haven't flown those yet. I may adapt down my LOC-IV down to 29mm to fly at CENJARS... but I digress.

The point is, things like how tight your nosecone needs to be you can only ascertain via experience, this isn't something you can google and get a good answer to. Tick-Tok doesn't help either. I think a lot of people think they can just waltz into this and get their "A" grade without doing actual work. Rocket Science isn't easy, just ask any rocket scientist!

Quote from Eric Becher on April 9, 2024, 7:50 pmThe ARC kids are not "Engineering Students". They are in high school and some of them happen to show some interest in engineering subjects, or perhaps just in rocketry. That does not make them engineers, and you shouldn't expect them to be.

Rather than complain about what they are doing wrong and chasing them away from the hobby, I would rather we show them how to do it right and encourage them to seek more success. I'm pretty sure that they are not intending to do things "wrong", just that they have not been shown a better way.

The ARC kids are not "Engineering Students". They are in high school and some of them happen to show some interest in engineering subjects, or perhaps just in rocketry. That does not make them engineers, and you shouldn't expect them to be.

Rather than complain about what they are doing wrong and chasing them away from the hobby, I would rather we show them how to do it right and encourage them to seek more success. I'm pretty sure that they are not intending to do things "wrong", just that they have not been shown a better way.

Quote from Eric Becher on April 9, 2024, 7:57 pmQuote from Brian C. on April 9, 2024, 6:19 pmI'm still not L1, although that is in my plans for this year.

Are you almost ready to do your L1?

I am planning to go for my L2 flight on Saturday, May 4th at MDRA (sod farm). Brian (Poohbah type) and Joe "Dr. Z" have kindly put this on their schedules to go with me and witness and sign off on it. If you have an H worthy rocket ready by then, perhaps you'd like to come along? Maybe fly a couple of other things too while we're at it.

Anybody else wanting to head down?

(Note, we plan to be back for our scheduled May 5th club launch)

Quote from Brian C. on April 9, 2024, 6:19 pmI'm still not L1, although that is in my plans for this year.

Are you almost ready to do your L1?

I am planning to go for my L2 flight on Saturday, May 4th at MDRA (sod farm). Brian (Poohbah type) and Joe "Dr. Z" have kindly put this on their schedules to go with me and witness and sign off on it. If you have an H worthy rocket ready by then, perhaps you'd like to come along? Maybe fly a couple of other things too while we're at it.

Anybody else wanting to head down?

(Note, we plan to be back for our scheduled May 5th club launch)