E12 Engine anti-CATO reinforcement

Quote from Eric Becher on July 6, 2022, 4:41 pmAs anyone who has attended our launches earlier this year knows, we have had a few CATO’s caused by Estes E12 engines. Essentially, the core of the engine burns uncontrolled and separates from the casing, traveling as a burning fireball past or through the rocket. Twice it traveled up the rocket body (once exiting through the side wall) and in another event it ejected out the bottom, then passed the rocket about 20ft above the pad. A little research online will show this has been an ongoing problem with these engines around the country.

We reported the issues to Estes, with pictures and video. They were apologetic and replaced the packages of engines and even provided rocket kits as replacements for the damaged rockets. (Kudos to Estes) But the question remains – are the replacement engines safe to use? Estes wouldn’t provide details on the cause, nor guarantee it wouldn’t happen again. I felt this left me in a bit of a dilemma. I don’t want to damage any more rockets than I absolutely have to.

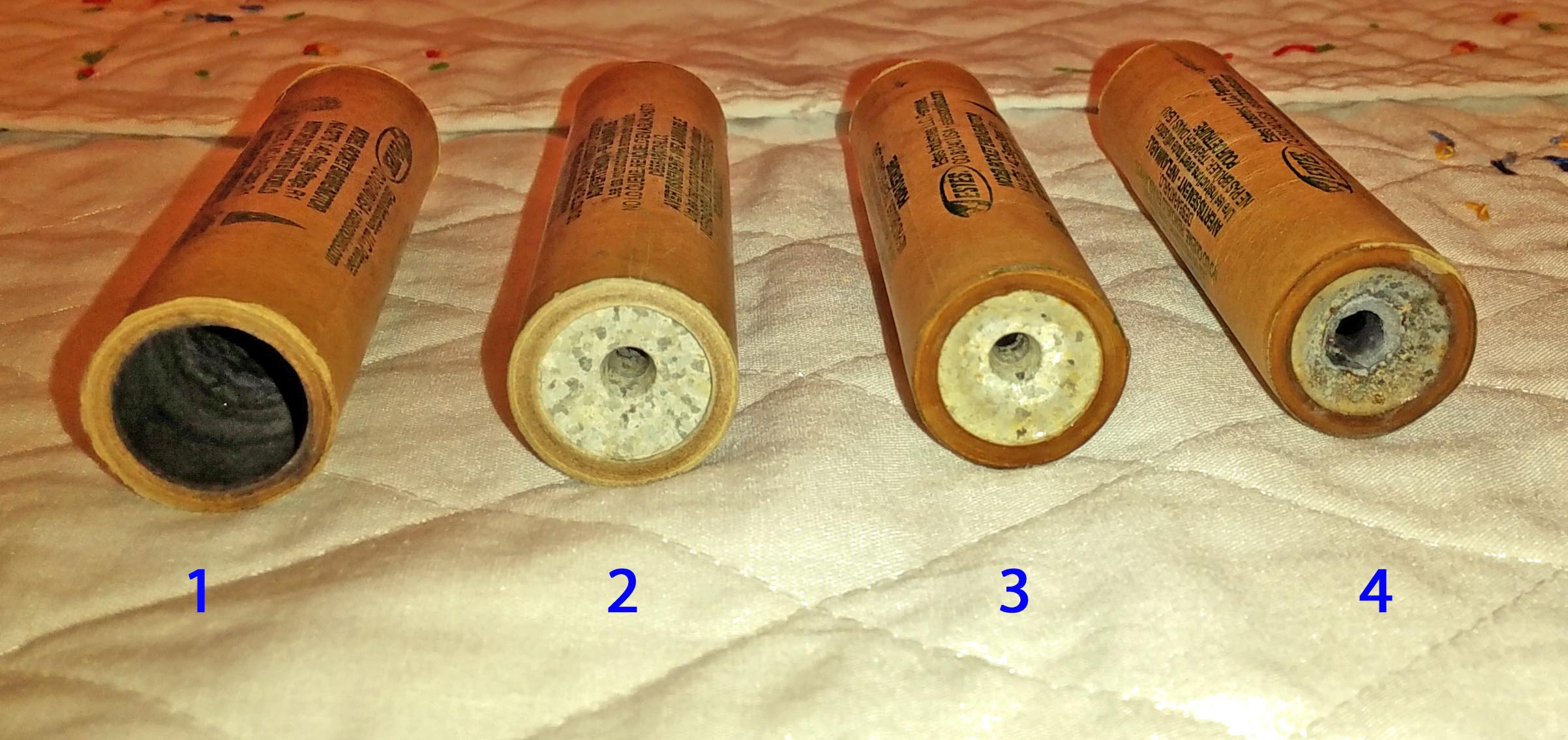

At our June launch there was another CATO of an E12. This time however, instead of blowing apart in the air, the event happened on the launch rod. I happened to look down at the debris under the pad and found the nozzle from the engine, looking fairly clean and unharmed. Previously this piece had been lost in the mid-air events. This time we had the “smoking gun.” While we (Brian and I, plus a few other Club members in post CATO discussions) suspected that a blown-out nozzle could have caused this, we didn’t have proof and Estes didn’t admit to anything other than that something went horribly wrong. In the picture “Engines”, casing 1 is from a CATO early this year. I noted that the casing seems to be in good shape, other than being burned as normal. There is no shredding or failure of the casing allowing the nozzle to come out.

At some point in the months that followed I wondered if I could add some “reassurance” to the nozzle to help keep it in place. My idea was to add epoxy around the rim of the nozzle where it meets the casing. Adding a little bit more security to the nozzle should be all that’s needed, assuming the nozzle has some kind of adhesive already, just perhaps a little inadequate for the job at times. It doesn’t need to be high temperature epoxy as we are only asking it to survive 2.7 seconds, and while the flame is close, it is not directly on it.

I know we are not supposed to modify engines for safety reasons, but I look at this as not modifying the engine by cutting, drilling or removing anything, but adding to the outside of the engine much like an engine mount tube is outside the casing.

In the “Engines” picture, casing 2 is an unaltered E12 engine. Casing 3 is an engine that has some 5 min epoxy worked around the edge of the nozzle and casing, including the end of the casing. Care must be taken to not get epoxy in the nozzle hole, interfering with the flow of exhaust. Note the lighter colored area near the nozzle hole where no epoxy was added. During the process I had a tapered dowel in the hole to prevent any epoxy from running into it. After spreading epoxy around the edges, I hung the engine with nozzle end downward to prevent any epoxy flow from going towards the opening. I was also careful not to get epoxy on the outside of the casing, which could prevent it from fitting into the engine mount. See picture “With epoxy” for a different view of a “reinforced” engine.

At the July launch I used one of the reinforced engines in my “USMMA” rocket (aka Estes’ Executioner). See “Engines” picture, casing 4. It was a normal flight and the engine looks normal, except for the line encircling the nozzle opening indicating the limits of the epoxy, which remains largely intact.

While this is by no means a “eureka” moment, at least the epoxy didn’t seem to cause an issue, and it withstood the launch well enough. More testing would have to be done with a significant number of reinforced and non-reinforced engines before any real conclusions are made. I don’t want to portray this as a guaranteed fix for the E12 problem. I only offer it as an idea should someone else besides me be losing sleep over the dilemma of how to use an E12 without risking their hard work on a nice rocket that could go up in a fireball. Until Estes can say they have fixed the problem, I may be reinforcing my E12’s from now on.

Of course, one could also avoid the Estes E12’s by flying something that requires F or G engines!

As anyone who has attended our launches earlier this year knows, we have had a few CATO’s caused by Estes E12 engines. Essentially, the core of the engine burns uncontrolled and separates from the casing, traveling as a burning fireball past or through the rocket. Twice it traveled up the rocket body (once exiting through the side wall) and in another event it ejected out the bottom, then passed the rocket about 20ft above the pad. A little research online will show this has been an ongoing problem with these engines around the country.

We reported the issues to Estes, with pictures and video. They were apologetic and replaced the packages of engines and even provided rocket kits as replacements for the damaged rockets. (Kudos to Estes) But the question remains – are the replacement engines safe to use? Estes wouldn’t provide details on the cause, nor guarantee it wouldn’t happen again. I felt this left me in a bit of a dilemma. I don’t want to damage any more rockets than I absolutely have to.

At our June launch there was another CATO of an E12. This time however, instead of blowing apart in the air, the event happened on the launch rod. I happened to look down at the debris under the pad and found the nozzle from the engine, looking fairly clean and unharmed. Previously this piece had been lost in the mid-air events. This time we had the “smoking gun.” While we (Brian and I, plus a few other Club members in post CATO discussions) suspected that a blown-out nozzle could have caused this, we didn’t have proof and Estes didn’t admit to anything other than that something went horribly wrong. In the picture “Engines”, casing 1 is from a CATO early this year. I noted that the casing seems to be in good shape, other than being burned as normal. There is no shredding or failure of the casing allowing the nozzle to come out.

At some point in the months that followed I wondered if I could add some “reassurance” to the nozzle to help keep it in place. My idea was to add epoxy around the rim of the nozzle where it meets the casing. Adding a little bit more security to the nozzle should be all that’s needed, assuming the nozzle has some kind of adhesive already, just perhaps a little inadequate for the job at times. It doesn’t need to be high temperature epoxy as we are only asking it to survive 2.7 seconds, and while the flame is close, it is not directly on it.

I know we are not supposed to modify engines for safety reasons, but I look at this as not modifying the engine by cutting, drilling or removing anything, but adding to the outside of the engine much like an engine mount tube is outside the casing.

In the “Engines” picture, casing 2 is an unaltered E12 engine. Casing 3 is an engine that has some 5 min epoxy worked around the edge of the nozzle and casing, including the end of the casing. Care must be taken to not get epoxy in the nozzle hole, interfering with the flow of exhaust. Note the lighter colored area near the nozzle hole where no epoxy was added. During the process I had a tapered dowel in the hole to prevent any epoxy from running into it. After spreading epoxy around the edges, I hung the engine with nozzle end downward to prevent any epoxy flow from going towards the opening. I was also careful not to get epoxy on the outside of the casing, which could prevent it from fitting into the engine mount. See picture “With epoxy” for a different view of a “reinforced” engine.

At the July launch I used one of the reinforced engines in my “USMMA” rocket (aka Estes’ Executioner). See “Engines” picture, casing 4. It was a normal flight and the engine looks normal, except for the line encircling the nozzle opening indicating the limits of the epoxy, which remains largely intact.

While this is by no means a “eureka” moment, at least the epoxy didn’t seem to cause an issue, and it withstood the launch well enough. More testing would have to be done with a significant number of reinforced and non-reinforced engines before any real conclusions are made. I don’t want to portray this as a guaranteed fix for the E12 problem. I only offer it as an idea should someone else besides me be losing sleep over the dilemma of how to use an E12 without risking their hard work on a nice rocket that could go up in a fireball. Until Estes can say they have fixed the problem, I may be reinforcing my E12’s from now on.

Of course, one could also avoid the Estes E12’s by flying something that requires F or G engines!

Uploaded files:Quote from Eric Becher on July 6, 2022, 9:12 pmWhat does a CATO look like? Here is a slowed down video of my above mentioned USMMA (Executioner) going not-so-ballistic. The fireball seen exiting the rocket is the engine core.

What does a CATO look like? Here is a slowed down video of my above mentioned USMMA (Executioner) going not-so-ballistic. The fireball seen exiting the rocket is the engine core.

Quote from John Falcone on August 4, 2022, 10:31 pmI've flown a lot of Estes E9s and E12s over the years and have only had one CATO. Luckily it was in a large E2X rocket called Red Flare that was a low effort build. Like you said, Estes made good on their warranty and sent me a new pack of engines. They also offered a replacement kit, but since the rocket wasn't damaged other than losing the launch lug (I think there was side force exerted when the nozzle blew out) I declined. When I received the engines Estes threw in a pack of launch lugs for me. Like you said, Eric, kudos to Estes on their customer service.

All that being said, I've come to the point where I won't put an E12 into anything I really care about. I saw a lot of them destroy beautiful rockets back at NSL 2018 in Geneseo, NY. I vividly recall an impeccably built Black Star Voyager just turn into saw dust from a particularly violent E12 CATO and making the decision then that I'd rather not be that guy lol. Nowadays I really only use them in a handful of rockets I have- an old Estes Maniac and the aforementioned Red Flare which are E2X kits, and an old Big Daddy that is pretty beat up from many flights.

I know Quest/Aerotech now makes a 24mm E26 QJet that might be a good alternative to the E12... although I'm not sure how much I trust them either after I had an 18mm C12 QJet blow up an old favorite a few years ago. Alas, CATOs are unfortunately an unavoidable part of the hobby, but I think its cool that maybe you're onto something with the epoxy "mod". Do you plan on making more to try and test?

I've flown a lot of Estes E9s and E12s over the years and have only had one CATO. Luckily it was in a large E2X rocket called Red Flare that was a low effort build. Like you said, Estes made good on their warranty and sent me a new pack of engines. They also offered a replacement kit, but since the rocket wasn't damaged other than losing the launch lug (I think there was side force exerted when the nozzle blew out) I declined. When I received the engines Estes threw in a pack of launch lugs for me. Like you said, Eric, kudos to Estes on their customer service.

All that being said, I've come to the point where I won't put an E12 into anything I really care about. I saw a lot of them destroy beautiful rockets back at NSL 2018 in Geneseo, NY. I vividly recall an impeccably built Black Star Voyager just turn into saw dust from a particularly violent E12 CATO and making the decision then that I'd rather not be that guy lol. Nowadays I really only use them in a handful of rockets I have- an old Estes Maniac and the aforementioned Red Flare which are E2X kits, and an old Big Daddy that is pretty beat up from many flights.

I know Quest/Aerotech now makes a 24mm E26 QJet that might be a good alternative to the E12... although I'm not sure how much I trust them either after I had an 18mm C12 QJet blow up an old favorite a few years ago. Alas, CATOs are unfortunately an unavoidable part of the hobby, but I think its cool that maybe you're onto something with the epoxy "mod". Do you plan on making more to try and test?

Quote from Eric Becher on August 8, 2022, 4:09 pmHi John!

Blowing up a good rocket that one has worked hard on really sucks! But if it doesn't fly, it isn't a rocket, so you have to take the risk.

Yes, I will keep trying the E12's for a bit. I have a handful already modified, but the weather at yesterday's Club launch was a little breezy, so I didn't use them. But I will, and when I have a little track record figured out, I'll post an update.

The Quest E26's sound like a good alternative. Maybe I'll give them a try too. It's just hard to beat the Estes availability.

Hi John!

Blowing up a good rocket that one has worked hard on really sucks! But if it doesn't fly, it isn't a rocket, so you have to take the risk.

Yes, I will keep trying the E12's for a bit. I have a handful already modified, but the weather at yesterday's Club launch was a little breezy, so I didn't use them. But I will, and when I have a little track record figured out, I'll post an update.

The Quest E26's sound like a good alternative. Maybe I'll give them a try too. It's just hard to beat the Estes availability.

Quote from Brian C. on December 7, 2022, 3:35 pmThe CATO at the December 2022 CENJARS launch has killed my "Drag Queen" rocket. I'm declaring the airframe a loss although the nosecone and payload section might be re-used on a Super Big Bertha that I've just ordered. I will contact Estes regarding the motor, although I just got from a set of replacement D motors from them after the CATO in October, so I hope I'm not pushing my luck with customer service.

I wonder if I could use CA rather than epoxy on the nozzle? I'll try one of each, and we'll do some experiments. As much as I prefer the "composite" 24mm motors, they are pricey -- the Estes E12's have the distinct advantage of being $18 for 3 at Hobby Lobby, which makes then $6 per flight, as opposed to Quest motors which can be around $12 to $15 per flight.

The CATO at the December 2022 CENJARS launch has killed my "Drag Queen" rocket. I'm declaring the airframe a loss although the nosecone and payload section might be re-used on a Super Big Bertha that I've just ordered. I will contact Estes regarding the motor, although I just got from a set of replacement D motors from them after the CATO in October, so I hope I'm not pushing my luck with customer service.

I wonder if I could use CA rather than epoxy on the nozzle? I'll try one of each, and we'll do some experiments. As much as I prefer the "composite" 24mm motors, they are pricey -- the Estes E12's have the distinct advantage of being $18 for 3 at Hobby Lobby, which makes then $6 per flight, as opposed to Quest motors which can be around $12 to $15 per flight.

Quote from Admin on December 7, 2022, 6:02 pmQuote from Brian C. on December 7, 2022, 3:35 pmThe CATO at the December 2022 CENJARS launch has killed my "Drag Queen" rocket. I'm declaring the airframe a loss although the nosecone and payload section might be re-used on a Super Big Bertha that I've just ordered. I will contact Estes regarding the motor, although I just got from a set of replacement D motors from them after the CATO in October, so I hope I'm not pushing my luck with customer service.

I wouldn't worry about pushing your luck. Estes is well aware of their problem and they should make good on their defective product.

I wonder if I could use CA rather than epoxy on the nozzle? I'll try one of each, and we'll do some experiments. As much as I prefer the "composite" 24mm motors, they are pricey -- the Estes E12's have the distinct advantage of being $18 for 3 at Hobby Lobby, which makes then $6 per flight, as opposed to Quest motors which can be around $12 to $15 per flight.

The nozzles are a compacted clay akin to that used in kitty litter. If the CA is thin-CA, it may soak in and bind the clay. I use thin-CA on balsa to add strength. It might work on the nozzles too.

Quote from Brian C. on December 7, 2022, 3:35 pmThe CATO at the December 2022 CENJARS launch has killed my "Drag Queen" rocket. I'm declaring the airframe a loss although the nosecone and payload section might be re-used on a Super Big Bertha that I've just ordered. I will contact Estes regarding the motor, although I just got from a set of replacement D motors from them after the CATO in October, so I hope I'm not pushing my luck with customer service.

I wouldn't worry about pushing your luck. Estes is well aware of their problem and they should make good on their defective product.

I wonder if I could use CA rather than epoxy on the nozzle? I'll try one of each, and we'll do some experiments. As much as I prefer the "composite" 24mm motors, they are pricey -- the Estes E12's have the distinct advantage of being $18 for 3 at Hobby Lobby, which makes then $6 per flight, as opposed to Quest motors which can be around $12 to $15 per flight.

The nozzles are a compacted clay akin to that used in kitty litter. If the CA is thin-CA, it may soak in and bind the clay. I use thin-CA on balsa to add strength. It might work on the nozzles too.

Quote from Eric Becher on December 7, 2022, 11:15 pmAs Poohbah says, Estes is well aware of the issue. I had CATOs this year at back to back launches. I submitted photos and videos. They replaced the engines AND the rocket kits, even though they weren't selling them anymore (had some leftovers on the shelf). In one case I told them it wasn't necessary since the damage was minor. They did so anyway. So don't sweat submitting another claim, as long as you have a picture, they shouldn't question it. If you need me to send you a picture, let me know. (I think what's in the gallery of the CATO was my pic).

Good luck!

As Poohbah says, Estes is well aware of the issue. I had CATOs this year at back to back launches. I submitted photos and videos. They replaced the engines AND the rocket kits, even though they weren't selling them anymore (had some leftovers on the shelf). In one case I told them it wasn't necessary since the damage was minor. They did so anyway. So don't sweat submitting another claim, as long as you have a picture, they shouldn't question it. If you need me to send you a picture, let me know. (I think what's in the gallery of the CATO was my pic).

Good luck!