Build help

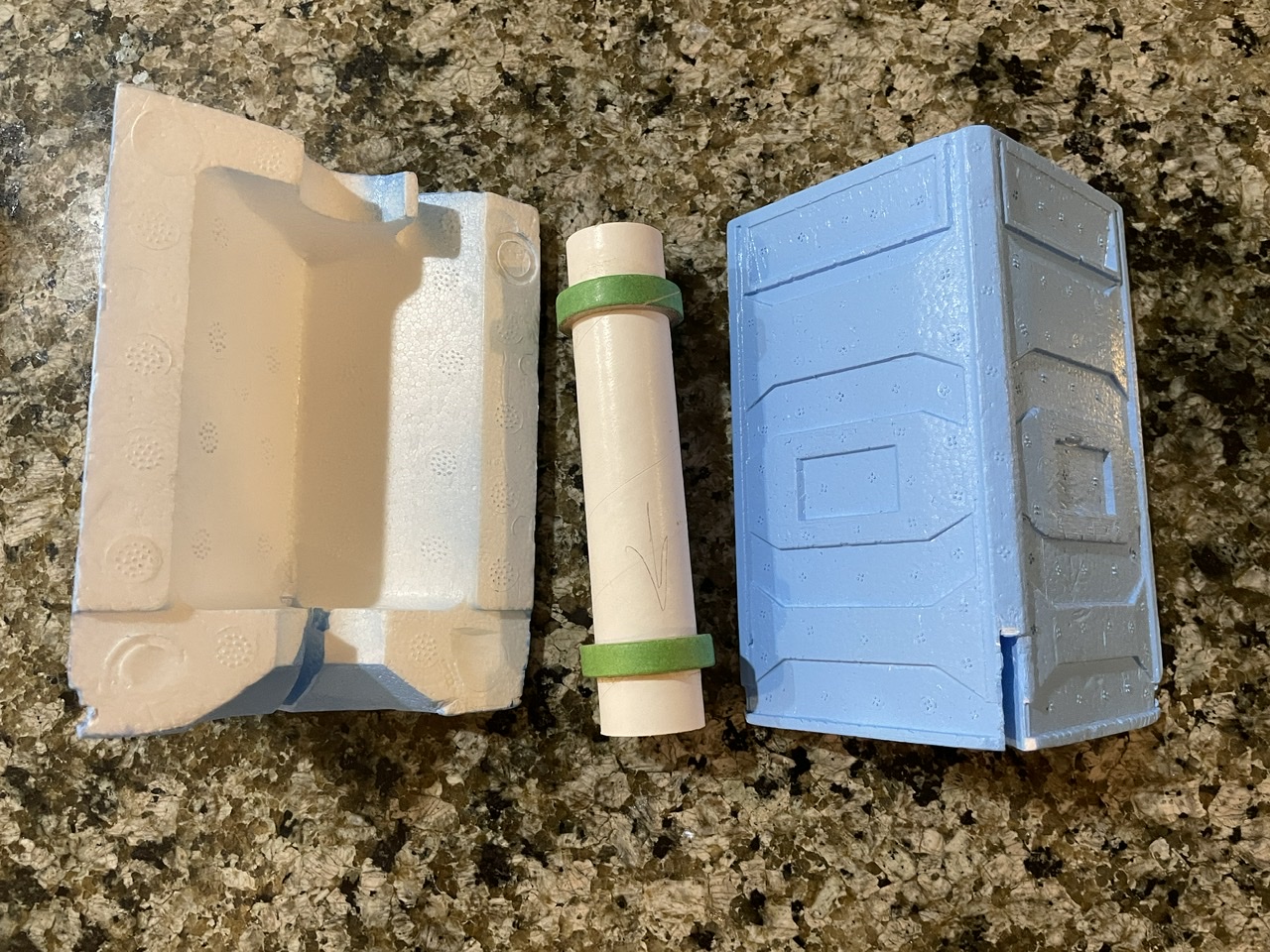

Quote from Zielijo1 on September 11, 2022, 6:20 pmI have the Estes Porta pot shot kit, it’s a flying Porta John. It’s 2 foam halves around a body tube. I’m making it 24mm bc it’s flies like a brick. Now the motor tube is closer to the foam

should I wrap/ tape the motor tube to keep the heat or wrap the foam to protect against the heat…

dryer duct tape? Good to 212F

thoughts?

Uploaded files:I have the Estes Porta pot shot kit, it’s a flying Porta John. It’s 2 foam halves around a body tube. I’m making it 24mm bc it’s flies like a brick. Now the motor tube is closer to the foam

should I wrap/ tape the motor tube to keep the heat or wrap the foam to protect against the heat…

dryer duct tape? Good to 212F

thoughts?

Quote from Eric Becher on September 11, 2022, 7:24 pmNormally I would say you should be better off protecting the foam by applying metal duct tape to the foam, but there are complications here. Looking at the directions, the body tube (which I guess is now the motor tube?) is supposed to be glued to the foam. Not sure what glue you're using, but many glues don't adhere to the metal tape as well. Make sure those spacers are glued well so they prevent the tube from exiting the foam caseing (working like a motor block).

The other issue I see is that the shock cord is to be glued to the body tube, now the motor tube. Bigger engine = bigger heat. I would use Kevlar and tie it around the tube. More heat resistant than rubber band shock cord.

Whichever way you go, make a good pre-fit before you glue it.

Good luck. I hope it doesn't fly like a bucket of crap!

Normally I would say you should be better off protecting the foam by applying metal duct tape to the foam, but there are complications here. Looking at the directions, the body tube (which I guess is now the motor tube?) is supposed to be glued to the foam. Not sure what glue you're using, but many glues don't adhere to the metal tape as well. Make sure those spacers are glued well so they prevent the tube from exiting the foam caseing (working like a motor block).

The other issue I see is that the shock cord is to be glued to the body tube, now the motor tube. Bigger engine = bigger heat. I would use Kevlar and tie it around the tube. More heat resistant than rubber band shock cord.

Whichever way you go, make a good pre-fit before you glue it.

Good luck. I hope it doesn't fly like a bucket of crap!

Quote from Ckirlew on September 11, 2022, 7:48 pmThe standards for the BP motors we use is to not have the exterior of the motor exceed 200 degrees C, about 400 degrees F. I don't know what the standards are for APCP motors. They could be a higher number so extra caution to keep heat away from the foam and any glue you use is a good idea.

The standards for the BP motors we use is to not have the exterior of the motor exceed 200 degrees C, about 400 degrees F. I don't know what the standards are for APCP motors. They could be a higher number so extra caution to keep heat away from the foam and any glue you use is a good idea.

Quote from VAXman on September 12, 2022, 6:42 amYou're over thinking this.

The OEM MMT is 18mm and you're wanting to put in 24mm MMT. That's only 2mm closer to the foam. If it's polystyrene foam, its melting point is higher than the vinyls and phenols in the adhesives of the paper MMT and that MMT is in closer proximity to the heat source (ie. the motor).

I'll let you borrow my Sears and Salinger treatise on Thermodynamics if you want to brush up.

You're over thinking this.

I'll let you borrow my Sears and Salinger treatise on Thermodynamics if you want to brush up.

Quote from Zielijo1 on September 13, 2022, 8:11 amThanks for the comments. No need for the textbook. Put me to sleep

this thing flies like my R2D2, so I will use a D12-3, just like R2

yes, the body tube is now the motor mount

only a portion of the MMT is in contact w the styrofoam. Looks like foam packaging from electronics purchases. I’m not gonna have it tested to determine its exact material

so, I can add dryer duct tape to the foam

no tape where the MMT needs to be glued

At what temp does styrofoam melt?

what glue? Franz mentioned CA for foam

would epoxy work? I also need to glue the fins, clear plastic attached to foam

thanks

Thanks for the comments. No need for the textbook. Put me to sleep

this thing flies like my R2D2, so I will use a D12-3, just like R2

yes, the body tube is now the motor mount

only a portion of the MMT is in contact w the styrofoam. Looks like foam packaging from electronics purchases. I’m not gonna have it tested to determine its exact material

so, I can add dryer duct tape to the foam

no tape where the MMT needs to be glued

At what temp does styrofoam melt?

what glue? Franz mentioned CA for foam

would epoxy work? I also need to glue the fins, clear plastic attached to foam

thanks

Uploaded files:

Quote from Eric Becher on September 13, 2022, 9:14 amStyrofoam starts to soften at 212 degrees F, and melts at 464 degrees. I don't think you have to worry about the inside of the Crapper case, just where your motor tube touches the foam. The way Estes designed it, with the motor tube inside a body tube and a space between, it wouldn't hurt the foam. Now that the space is gone, the heat transfers much better. But I'd be hopeful that it won't hurt the foam too much.

Probably the best thing you can do is get to the thing right after landing and get the hot motor out of it asap.

Epoxy might work without melting the foam, but I never tried it. Test it with a drop on an inside part.

Styrofoam starts to soften at 212 degrees F, and melts at 464 degrees. I don't think you have to worry about the inside of the Crapper case, just where your motor tube touches the foam. The way Estes designed it, with the motor tube inside a body tube and a space between, it wouldn't hurt the foam. Now that the space is gone, the heat transfers much better. But I'd be hopeful that it won't hurt the foam too much.

Probably the best thing you can do is get to the thing right after landing and get the hot motor out of it asap.

Epoxy might work without melting the foam, but I never tried it. Test it with a drop on an inside part.

Quote from Admin on September 13, 2022, 10:16 amQuote from Zielijo1 on September 13, 2022, 8:11 amThanks for the comments. No need for the textbook. Put me to sleep

Really, I found it quite exasperating for a semester.

this thing flies like my R2D2, so I will use a D12-3, just like R2

yes, the body tube is now the motor mount

only a portion of the MMT is in contact w the styrofoam. Looks like foam packaging from electronics purchases. I’m not gonna have it tested to determine its exact material

High-density closed-cell polystyrene. Eric's comment on the melting point is correct. (210ºC-250ºC). However, do not confuse temperature with heat (Q). For instance, a candle burns at around 1000ºC but it only produces about 80J/s. Don't throw your heating system out just yet for a subscription to the Yankee Candle of the Month club.

so, I can add dryer duct tape to the foam

no tape where the MMT needs to be glued

At what temp does styrofoam melt?

what glue? Franz mentioned CA for foam

would epoxy work? I also need to glue the fins, clear plastic attached to foam

I picked up a great foam glue at the last AMA Expo. Many model aviation gliders are HDCC polystyrene. Sadly, I don't know the name of the vendor.

That said, most craft hobby shops should have a decent foam glue/adhesive that would work.

DO NOT USE CA (cyanoacrylate/super glue). It will QUICKLY dissolve the polystyrene. Both Charlie and myself can attest to that after having built the Apogee Saturn V which has vacuformed polystyrene wraps. Apogee recommends using thin-CA to adhere them to the paper body tubes but the use of it has to be done very sparingly.

Plastruct Bondene, which is MEK and xylene, might work to bond the plastic fins to the styrofoam. I'd test the foam on the inside before using it to see how much it will dissolve the foam. Bondene is a great plastic (polystyrene) model solvent cement. You put the pieces together and dab a little of the Bondene on the joint. For acrylic, I use methylene chloride which would certainly consume that foam.

If you're going to use epoxy, try BSI 30-minute. It'll cure slowly, produce little heat and it will bond with the foam OK. The smooth plastic of the fins should be roughed up where the epoxy will be applied.

Quote from Zielijo1 on September 13, 2022, 8:11 amThanks for the comments. No need for the textbook. Put me to sleep

Really, I found it quite exasperating for a semester.

this thing flies like my R2D2, so I will use a D12-3, just like R2

yes, the body tube is now the motor mount

only a portion of the MMT is in contact w the styrofoam. Looks like foam packaging from electronics purchases. I’m not gonna have it tested to determine its exact material

High-density closed-cell polystyrene. Eric's comment on the melting point is correct. (210ºC-250ºC). However, do not confuse temperature with heat (Q). For instance, a candle burns at around 1000ºC but it only produces about 80J/s. Don't throw your heating system out just yet for a subscription to the Yankee Candle of the Month club.

so, I can add dryer duct tape to the foam

no tape where the MMT needs to be glued

At what temp does styrofoam melt?

what glue? Franz mentioned CA for foam

would epoxy work? I also need to glue the fins, clear plastic attached to foam

I picked up a great foam glue at the last AMA Expo. Many model aviation gliders are HDCC polystyrene. Sadly, I don't know the name of the vendor.

That said, most craft hobby shops should have a decent foam glue/adhesive that would work.

DO NOT USE CA (cyanoacrylate/super glue). It will QUICKLY dissolve the polystyrene. Both Charlie and myself can attest to that after having built the Apogee Saturn V which has vacuformed polystyrene wraps. Apogee recommends using thin-CA to adhere them to the paper body tubes but the use of it has to be done very sparingly.

Plastruct Bondene, which is MEK and xylene, might work to bond the plastic fins to the styrofoam. I'd test the foam on the inside before using it to see how much it will dissolve the foam. Bondene is a great plastic (polystyrene) model solvent cement. You put the pieces together and dab a little of the Bondene on the joint. For acrylic, I use methylene chloride which would certainly consume that foam.

If you're going to use epoxy, try BSI 30-minute. It'll cure slowly, produce little heat and it will bond with the foam OK. The smooth plastic of the fins should be roughed up where the epoxy will be applied.

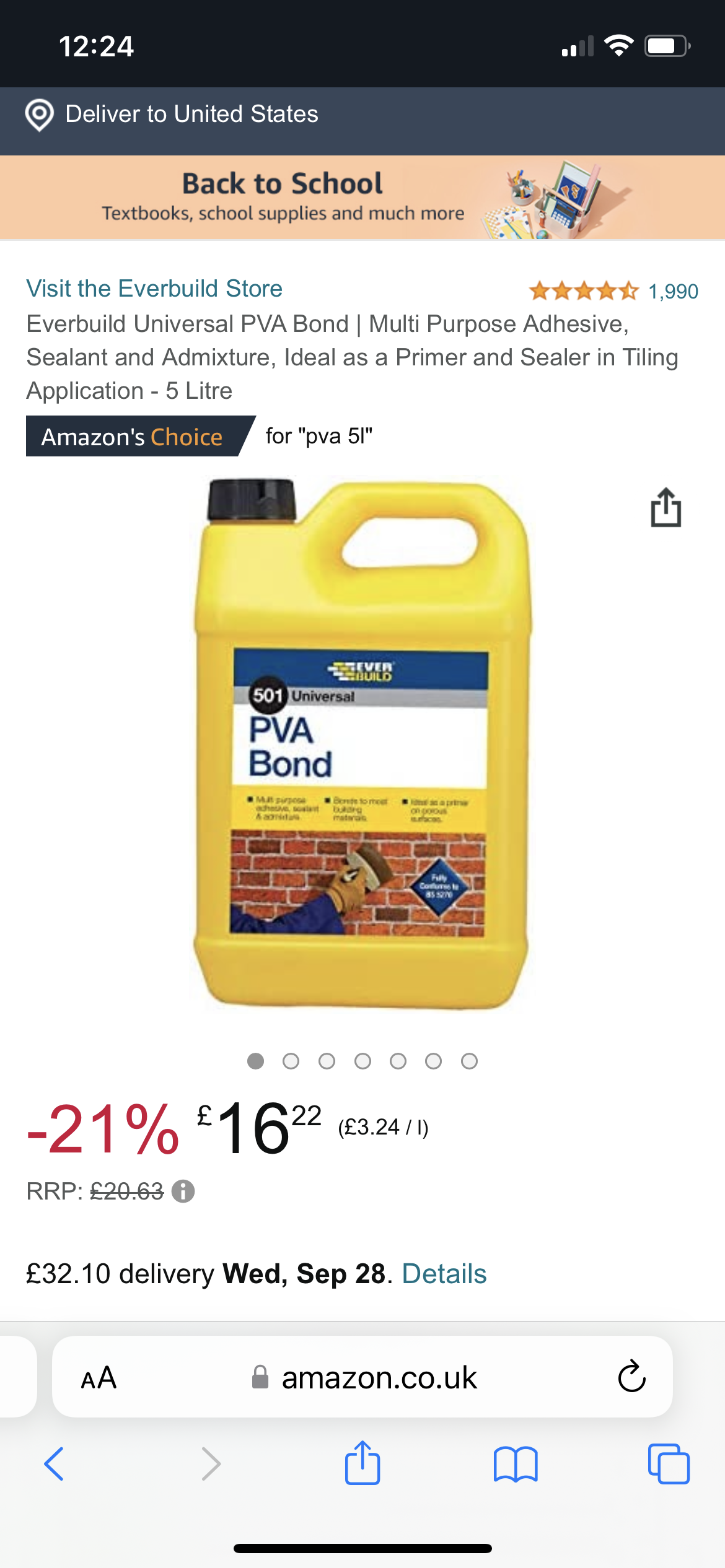

Quote from Zielijo1 on September 13, 2022, 12:27 pmI’ve done some research. Styrofoam is used as insulation on buildings. Construction adhesive for styrofoam should work.

a ref article recommended this glue as wellthoughts?

I’ve done some research. Styrofoam is used as insulation on buildings. Construction adhesive for styrofoam should work.

a ref article recommended this glue as well

thoughts?

Uploaded files:

Quote from Eric Becher on September 13, 2022, 5:00 pmSeems like a large container for your needs, but what do I know.

Never used the stuff myself, but they are putting it on my father in law's apartment building as we speak. Looks kinda like varnish. I'm a little doubtful about its adhesive quality, but I don't really know.

You can get construction adhesive (liquid nails) at home depot or wherever, but read the instructions and it should say if it's ok on foam. The stuff is thick like caulk though.

Seems like a large container for your needs, but what do I know.

Never used the stuff myself, but they are putting it on my father in law's apartment building as we speak. Looks kinda like varnish. I'm a little doubtful about its adhesive quality, but I don't really know.

You can get construction adhesive (liquid nails) at home depot or wherever, but read the instructions and it should say if it's ok on foam. The stuff is thick like caulk though.